News Center

What are the four main reasons for the heating of the power module

2021-12-11

Touch the surface of the power module. It's warm. Is the module broken? Wait a minute, there is a little fever, just because it is working hard. However, high temperature has a great impact on the reliability of the power module! Based on the knowledge of power module thermal design, this time, we will find out the cause of power module heating. The power module has energy loss in the process of voltage conversion, which generates heat energy to cause module heating, reduces the conversion efficiency of the power supply, affects the normal operation of the power module, and may affect the performance of other devices around it. This situation needs to be checked immediately. But under what circumstances will the power module heat seriously? The specific reasons are as follows:

1、 Linear power supply is used

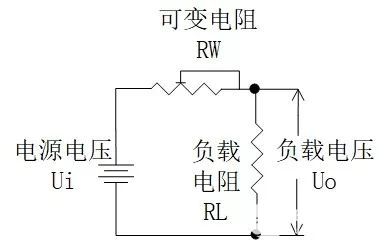

The working principle of the linear power supply is shown in Figure 1 below. The output voltage can be changed by adjusting the RW of the adjusting tube. Since the adjusting tube is equivalent to a resistor, the current will heat up when passing through the resistor, resulting in low efficiency.

Figure 1 Schematic diagram of linear power supply

In order to prevent serious heating of the power supply module, the following measures can be taken: increase the heat sink, implement air cooling, solve the problem of thermal conductive materials (thermal conductive silicone grease, thermal conductive potting adhesive), and switch to the switch power supply.

2、 Load overcurrent

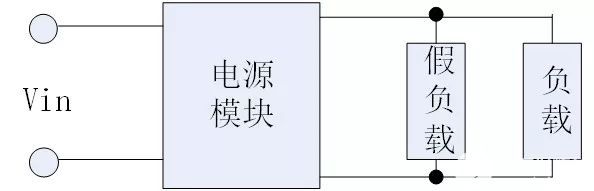

The overload of power supply is the opposite of the light load of power supply. The load circuit of the power supply circuit has a short circuit, which makes the power supply circuit output a large amount of current, which is beyond the range of the power supply. For the power supply module without overcurrent protection, the simplest way to output voltage stabilization, overvoltage and overcurrent protection is to connect a linear regulator with overcurrent protection at the input end, as shown in Figure 3.

Figure 2 Load overcurrent, adding linear regulator

3、 The load is too small

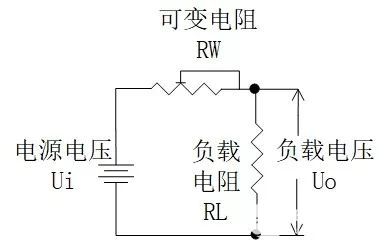

Light load of the power supply means that the load impedance of the power supply circuit is relatively large, and the output current of the power supply to the load is relatively small. Light load of power supply is not allowed in some power supply circuits, otherwise the DC working voltage output by the power supply circuit will rise a lot, causing damage to the power supply circuit. Generally, the power supply module has the minimum load limit, which varies from manufacturer to manufacturer, generally about 10%. If the output load is too light, it is recommended to parallel a dummy load resistor at the output end, as shown in Figure 2. The sum of the false load resistance power and the actual load power is more than 10% of the load.

Fig. 3 The load is too small, and the parallel dummy load

4、 High ambient temperature or poor heat dissipation

Before using the module power supply, be sure to consider the temperature level of the power supply module and the actual required operating temperature range. Derating design is carried out according to load power and actual ambient temperature.

Hot news

2021-12-25

Guangdong Guangxin Photoelectric Technology Co., Ltd Ending of excellent operation management projectGuangdong Guangxin Photoelectric Technology Co., Ltd In order to improve the management level of the company, better meet and serve customers, and speed up the response to customers, the company has carried out the excellent operation management project w

2021-12-15

Guangdong Guangxin Photoelectric Technology Co., Ltd Go to Jiangsu to serve customers in the East China market with LED drive power supplyGuangdong Guangxin Photoelectric Technology Co., Ltd Production and sales of LED light drive power supply (LED drive power supply), with rich product lines, mainly based in Guangdong for many years; However, there are many LED lamp manufacturers in Jiang

2021-12-11

FAQ of LED drive power supplyThe LED driver we mentioned includes digital driver and analog driver. Digital driver refers to digital circuit driver, including digital dimming control, RGB full-color change, etc. Analogue drive refers to analog circuit drive, including AC constant cur

Copyright © Guangdong Guanx Photoelectric Technology Co., Ltd All Rights Reserved 粤ICP备2021156941号-1

Website Construction:LEEKIND